CUSTOM GEAR MANUFACTURING

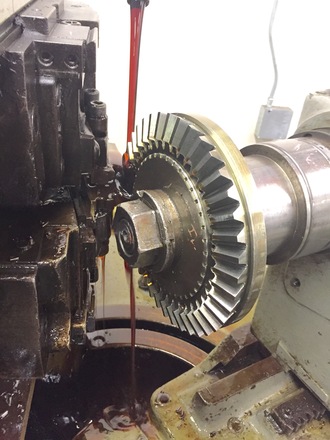

At Industrial Sprockets & Gears, Inc. we provide custom manufacturing of gears for a wide variety of industries. Our extensive machining capabilities can manufacture gears up to 30’ in diameter to suit large-scale mechanical power of transmission applications.

We manufacture a full range of gear types including, but not limited to, spur, helical, herringbone, straight bevel, miter, worm, racks, and sprockets. Utilizing a state-of-the-art 250 ton vertical press, gears are precisely cut using machining capabilities that include milling, conventional and climb hobbing, thread milling, turning, broaching, key seating, shaping, EDM, and flame cutting.

With the capability to work with metals, alloys, and plastics, we can meet the needs of almost any customer. In addition to 30’ diameter gears, we can also produce bore diameters up to 11’, for gears that weigh up to 60,000 lb.

As a complete machine shop, we have the capability to manufacture custom gears to exacting specifications and also handle gearbox overhauls and line boring. We offer the highest quality gears in the industry with complete customer satisfaction. Our 24 hour emergency service guarantees that we will be available to keep your machinery up and running.

For complete details on our custom gear manufacturing service please see the table below or contact us today.

CUSTOM GEAR MANUFACTURING CAPABILITY

- Gear Types

-

Spur

Helical

Herringbone

Straight Bevel

Miter

Worm

Tangential Worm Cutting

Spiral Bevels

SprocketsSilent Chain Sprockets

Gilmer Timing Gears

HTD Power Grip Gears

Helical Gear Rack

Involute Splines

SAE Splines

Racks

Sprockets

Roller Chain

- Gear Tooth Forms

-

Straight

Involute

Fellows 20˚ Stub Tooth SystemBritish Standard Metric

Cycloidal

- Gear Cutting Method

-

Milling

Conventional Hobbing

Climb Hobbing

Thread Milling

TurningBroaching

Keyseating

Shaping

EDM

Flame Cutting

- Gear Forming Method

-

Vertical Press

- Materials

-

Stainless Steel

Aluminum

Brass

Bronze

Carbon MaterialsAlloy Materials

Nitronic Materials

Plastic

Nylatron

Food Grade Plastic (Delrin)

- Gear Finishing Methods

-

Lapping

HoningShaving

Plating

Grinding

- Heat Treatment Methods

-

Carburizing

FlameInduction

Nitriding

- Diameter

-

Up to 30 ft.

Up to 360 in

- Bore Diameter

-

Infinite

- Spur / Helical Face

-

Up to 110″

- Spur / Helical Circular Pitch

-

3/16 to 6 in

- Spur Metric Module

-

1 to 24 mm

- Spur Pressure Angle

-

14.5°

20°22.5°

25°

- Diametral Pitch

-

1/2 to 120 DP

- Helix Angle

-

Up to 45°

- Heringbone Diameter

-

Up to 63 in

- Heringbone Face

-

Up to 24 in

- Bevel Gear Diameter

-

Up to 40 in (Coniflex, 1 DP)

- Bevel Gear Face

-

Up to 6 in

- Miter Gear Diameter

-

Up to 48 in (Straight, 1 DP)

- Miter Gear Face

-

Up to 6 in

- Spiral Bevels

-

Up to 40 in

- Sprocket Outside Diameter

-

Up to 360 in

- Sprocket Pitch

-

1/4 to 3 in

- Silent Chain Sprocket Pitch

-

3/16 to 3 in

- Gilmer Timing Gear Pitch

-

1/5 to 1-1/4 in

- HDT Power Grip Gears

-

8 mm

14 mm

5 mm

- Involute Splines / SAE Splines

-

Internal

External

- Rack Face

-

Up to 24 in

- Keyseating Width

-

3/16 to 6 in

- Keyseating Length

-

Up to 54 in

- Thread Milling Outside Diameter

-

Up to 14 in

- Thread Milling Thru Spindle

-

Up to 6 in

- Vertical Press Capacity

-

250 ton

- Part Weight

-

Up to 60,000 lb.

- Production Volume

-

Prototype to Large Scale Production Volume Run

- Lead Time

-

24 hour Emergency Service Available

Additional Information

- Industry Focus

-

Cement & Salt

Paper & Pulp

MiningPlastics

Automotive

Asphalt

- Industry Standards

-

ASTM

AGMA

- File Formats

-

AutoCAD

PDF

Images