Gear Grinding and Heat Treating for the Petroleum Industry

The ground gears we manufacture at Industrial Sprockets & Gears, Inc. include external, internal spur, helical gears, and worm gears.(Single lead or multiple start) Ground gears are an ideal choice to extend the life of equipment and gain an increase in gear performance. Our team has the technology to provide precision ground gears in a wide array of sizes and geometries.

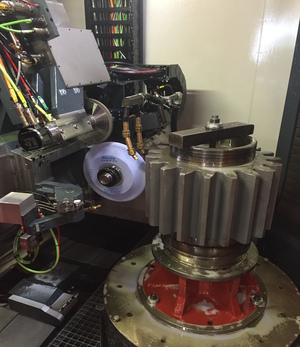

For the project highlighted here, we produced 15 ground gears for a customer in the petroleum industry who is located in India. The gears are made from 4140 heat treated steel and have an outer diameter of 22” with a 3″ gear face. To produce these gears, a CNC lathe, gear hobbing machine, and boring mill were used. Each process was performed by skilled machinists with a wealth of experience in their craft and training on the latest CNC machining equipment. AGMA Class 12 quality standards, which include dimensional tolerances as tight as ±0.001″ were held during machining, in accordance with customer specifications. To add to the challenge of this project, the design of this gear features a thin wall behind the gear tooth, which required special consideration to maintain concentricity.

The customer chose us for this project as a result of our strong reputation for quality within the gear manufacturing industry as well as our ability to turn around projects quickly. For this project, all 15 gears were produced with a lead time of three weeks. The customer provided very positive feedback regarding the quality of the finished gears and our ability to provide the gears on-time, in accordance with their desired delivery schedule. For additional details regarding this custom ground gear machining project, see the table below, or contact us directly.

GROUND GEAR PROJECT HIGHLIGHTS

- Product Description

-

Ground gear

- Equipment Used to Manufacture Part

-

Lathe, gear hobbing machine, boring mill

- Overall Part Dimensions

-

22in OD x 3in face

- Tightest Tolerances

-

.001

- Material Used

-

4140 heat treated

- Material Finish

-

ground

- In process testing/inspection performed

-

ISG inspected

- Estimated Part Weight

-

60 lbs

- Industry for Use

-

petroleum

- Delivery Location

-

India

- Standards Met

-

AGMA quality #12

- Volume

-

15

- Delivery/ turnaround Time

-

3 weeks